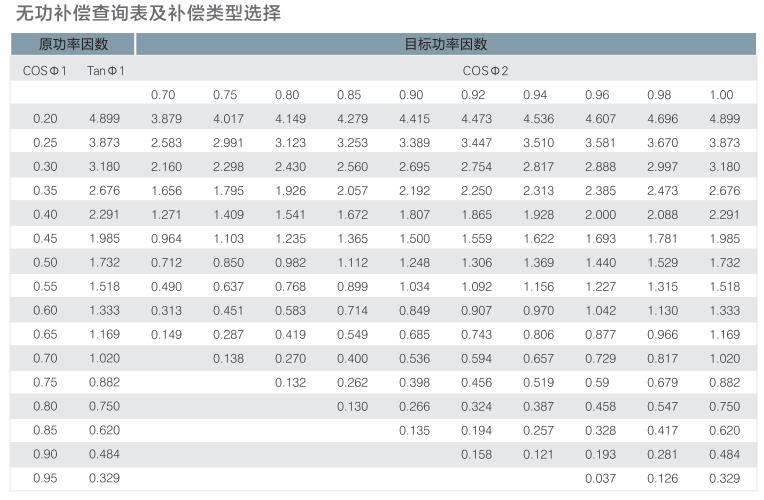

Product features

Design and characteristics of parallel capacitors

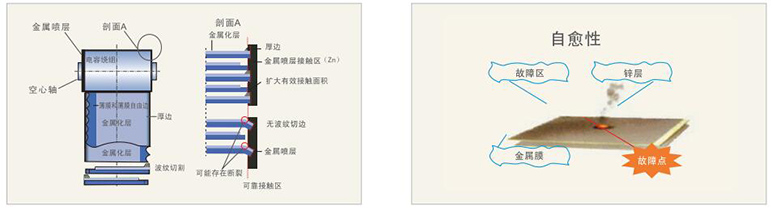

Microwave pattern edge cutting technology

The RUC capacitor adopts a thickened (8 μ m/9 μ m) self-healing metallization film coated with special metal components. By adopting a special corrugated edge cutting design, the effective metal spraying area on the side of the component winding is increased by 20%, which greatly strengthens the component and its additional connection points, playing an important role in resisting large currents and ensuring the stability of the capacitor.

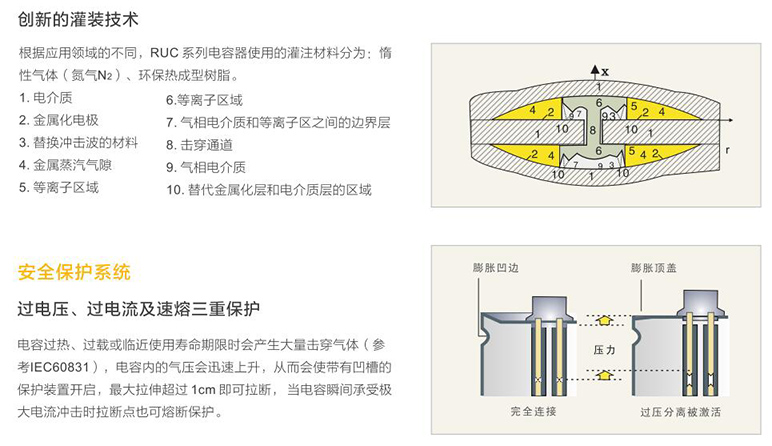

self-healing

When the capacitor experiences overvoltage, overcurrent, or near its service life, it is highly likely to experience breakdown, and the metallized layer can be broken down and evaporated within a few microseconds. At this point, an insulation area without a metallized layer will be formed in the breakdown area (this area will not participate in the charging and discharging process when it exits work). After breakdown occurs, the capacitor can function normally. Due to self-healing, the capacity loss caused by self-healing is less than 100PF. By using high-quality metallized films, the self-healing density of the product can reach over 70%.

Strict inspection requirements

RUC capacitors comply with 100% component testing standards, and all components undergo strict quality testing before capacitor assembly to ensure the electrical performance and safe service life of the capacitor:

1、Winding detection

2、Loss detection

3、Self healing testing

4、High temperature tolerance testing

5、Capacitance tolerance detection

6、Voltage withstand test

characteristic

Electrical aspect

Long service life ≥ 115000 hours

High surge current resistance (200In)

Security

self-healing

Overpressure separator

Anti electric shock terminal

Pre installed discharge module

Mechanical and maintenance aspects

Reduced assembly costs

Easy to install and connect

Lightweight and compact in size

Maintenance free

environment protection

Dry design

Injecting inert gas

Oil free